Brought to you by Claude Chanson from RECHARGE

By identifying stocks and flows of products in the urban mine, FutuRaM has the potential of contributing to the establishment of a truly circular economy. Particularly when it comes to technology products in the scope of FutuRaM (batteries, electronic and vehicles), providing valuable metals and alloys, that can be endlessly recycled without any loss of properties.

However, another characteristic of these products is often underestimated: it is the complexity of their composition. We can take the example of the DIY (Do It Yourself) tools market. Of course, some of these tools remain quite simple: a hammer consists of a wooden handle and a steel head. A saw is made of a metallic frame and a steel blade. However, fewer and fewer people are using a simple saw, and the market is clearly developing in the direction of much more sophisticated tools: first moving from a saw to an electric saw, then to a cordless electric saw, updated with a LED lighting, and soon to include a touchscreen. As a result, the complexity of this type of tool is continuously increasing, and the same trend is observed for most technology products. The typical composition of an electronic product can now contain several dozens of materials. In addition, these materials have a specialised use, as they have been introduced to provide specific functions. For example, Lithium, Cobalt, and Nickel are active materials of batteries; Gallium and Silicon are components of LED and other electronics; while Neodymium-Iron-Boron is used for certain permanent magnets of electric motors.

Due to this complexity, it is becoming inevitable that some of the materials used in technology products have hazardous properties.

- Numerous substances have been characterised as hazardous: the number of substances of very high concern (SVHC) is now 235.

- However, the number of “substances of concern” is several thousand while the application of these substances is rising even higher. Particularly, as many metals, metal salts, and oxides have hazardous properties.

- Not only is the number of substances identified as hazardous is growing fast thanks to the classification process of the ECHA (European Chemical Agency), but also the list of identified hazards included in the classification, labelling, and packaging of substances and mixtures (CLP) regulation currently under revision. The hazard endpoints of persistent, mobile, and toxic (PMT), very persistent and very mobile (vPvM) have been added.

Briefly put, the presence of multiple hazardous substances in complex products (such as electric/electronic equipment, vehicles, industry, and infrastructure equipment, etc.) is inevitable.

How to control the risk caused by hazardous substances in technology products to achieve a “perfect” circular economy?

1. Eliminate the hazardous substances

Let us take the example of plastics recycling. Plastics containing certain toxic anti-oxidizing additives cannot be used for food-safe containers and water bottles. Which implies the need of a new plastic recycling loop excluding the substances in question. This solution is currently under application.

On the other hand, the complexity of technology products creates a completely different situation, and this approach becomes unapplicable. The potential success of finding substitutions with non-hazardous substances for technology products in the coming years is exceptionally low or even, non-existent.

Substances with certain physio-chemical properties are used for specific services and hence are difficult to replace. They are not only scarce in nature but took decades of research to identify and match with the right technical solution serving (current) market needs.

Moreover, technological developments and competition are permanently enabling product design upgrades, ultimately making studies for substitution of hazardous substances lag behind.

Therefore, the elimination of hazardous substances from technology products seems out of reach, a nice, but unrealistic dream. The objective of completely removing hazardous substances from complex products is seemingly not achievable in a competitive world. This objective has never been assessed as such, and therefore should not be used as a driver for any European regulation.

2. The Essential Use Concept

A recent case study of the per- and polyfluoroalkyl substances (PFAS) restriction is clearly raising the question of the continued use of hazardous substances when they cannot be substituted. Should the essential use concept (EUC) be applied to limit the use of hazardous substances solely in products that are critical for the functioning of society? The purpose and implementation of the EUC are raising major concerns:

It is not a solution that contributes efficiently to the prevention of harm caused by hazardous chemicals.

The EUC opens the possibility of continuing the application of hazardous chemicals due to their use, instead of having to demonstrate that an acceptable level of protection is achieved when a substitution is not available. This approach will result in comparing the potential – and general – harm caused by hazardous substance production and use, and the potential harm that could be prevented by the specific use of the particular substance. For example, in the use of PFAs for electromobility, should we compare the need to reduce the impact of low air quality in urban areas to the impact of PFAs present in drinking water as assessed in the PFAs restriction proposal? The objective should be to control the risk in both cases, and not to generate discussions on contradictory approaches: the clean air control versus the chemical risk control.

Question of Enforceability

The number of applications of hazardous substances is much too large to be controlled for each and every case. A perfect example of this, is the recorded number of comments – 5600 – in this PFAs restriction case. Consequently, this approach will open an endless debate on which usages are essential and for which actor? Defining essential use as “critical for society” is not helpful standing on its own, as it does not clearly define what “critical” means, neither who are the representatives of “society.” At last, simple cases where decision making is easy (such as medical use as mentioned in The Montréal Protocol) rarely happen in reality.

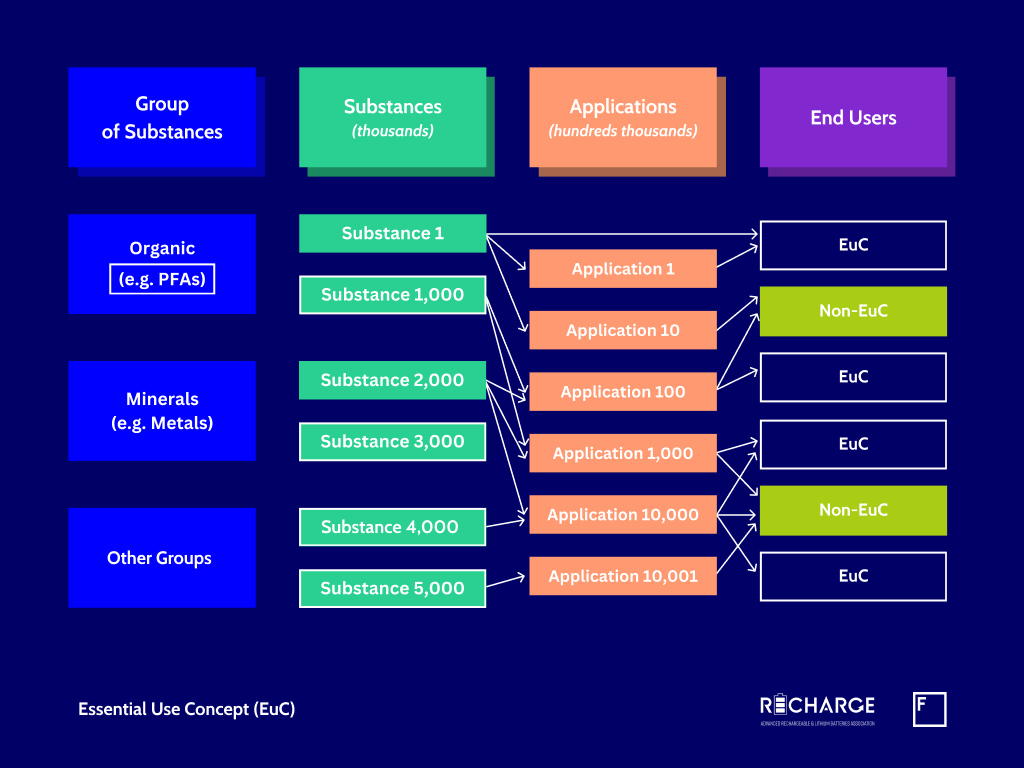

The following diagram illustrates the complexity of the Essential Use Concept and its implementation when considering the complexity of the market (number of applications).

Simply put, the admission of hazardous substances used cannot be correctly tracked. Evidence can be found in the ECHA SCIP database, where large inconsistencies are easily observed (for example here, where incoherent lists are presented) but the studies realised by ECHA already recognise that the regulation about restricted substances in articles is not respected. This is a significant limit to the implementation. Therefore, the operational control of the presence of substances in an article manufactured or imported in EU (European Union) cannot be achieved, unless each and every article is manufactured under third party control. Another seemingly unrealistic dream.

3. Control the risk of hazardous substances during the entire life cycle

The principle of prevention of harm is the fundamental principle of the REACH Regulation, based on a risk control approach. In addition, the requirement to control the chemical risk is complemented by multiple other EU regulations such as the Industrial Emissions Directive, the Waste Framework Directive, or Health and Safety at Work regulations.

Undoubtedly, examples can be found where a stronger implementation, or an update of these regulations is needed. Luckily, this is already ongoing: the most recent Batteries Regulation covers Extended Producer Responsibility (EPR) concerning the obligation of to ensure that batteries will be recycled, and that key material(s) will be recovered. The general trend of reinforcing EPR measures may be observed for all technology products and is naturally driving the development of professional recycling where the risks of hazardous substances are correctly controlled. In this case, the presence of hazardous substances will not prevent recycling. On the contrary, in some of these cases, the hazardous substances are indeed the valuable materials that facilitate the economic viability of recycling and the circular economy.

What is next?

Efforts should be made to continue ensuring that the risk control of hazardous chemicals is correctly implemented for all usages liable to harm society. Particularly, the quality recycling of all valuable substances, including the safe manufacturing, use and recycling of hazardous chemicals, should be promoted for technology products, rather than aiming at removing or limiting these substances. This might be the only way to approach the dream of a perfect circular economy.