Brought to you by Robert Šajn and Jasminka Alijagić from the Geological Survey of Slovenia

What are Secondary Raw Materials?

Secondary raw materials (2RMs) are recycled materials that can be used in manufacturing processes instead of or alongside virgin raw materials. In mining and metallurgy, they typically include waste materials (e.g., mine tailings), side streams (e.g., slags and ashes), processing residues – the material that is removed during the product life cycle – and the products and their materials that have reached the end of their life cycle. In a circular economy context, 2RMs can be traded and shipped in the same way as primary raw materials from traditional extractive resources, which increases the security of supply but also reduces pressure on natural resources.

A pragmatic definition can also be derived from the extractive industry legislation such as Extractive Waste Directive and the legal definitions of waste and waste management hierarchy regulated by the Waste Framework Directive. In this context, 2RMs are materials and products that can be used as raw materials through simple re-use, or recycling and recovery.

The Potential of Mining Waste, Slags, and Ashes

2RMs from tailings are readily available materials that could be converted into potential reserves. However, the reserves are the basis for the extraction plan, while the extraction plan is the centrepiece of the business plan. Mineral resources lay the groundwork for the assessment of mining company worth, while risk management plays a vital role in guiding business decision-making processes.

The countries of South-East Europe (SEE) have the potential to extract raw materials from primary and secondary raw material deposits and can increase their self-sufficiency in raw materials by using appropriate, modern, and eco-efficient technology.

Underlining the potential of these deposits, several European projects have conducted research in the area such as RESEERVE, RIS-CuRE, RIS-RECOVER, RECO2MAG, and now FutuRaM. This case study, prepared by project partners from the Geological Survey of Slovenia and University of Belgrade, for example, is dissecting mining and metallurgical waste as potential secondary sources of metals. While this scientific paper co-authored by University of Leoben, is researching the chemical and mineralogical characterisation of tailings from base metal sulfide deposits in Serbia and North Macedonia.

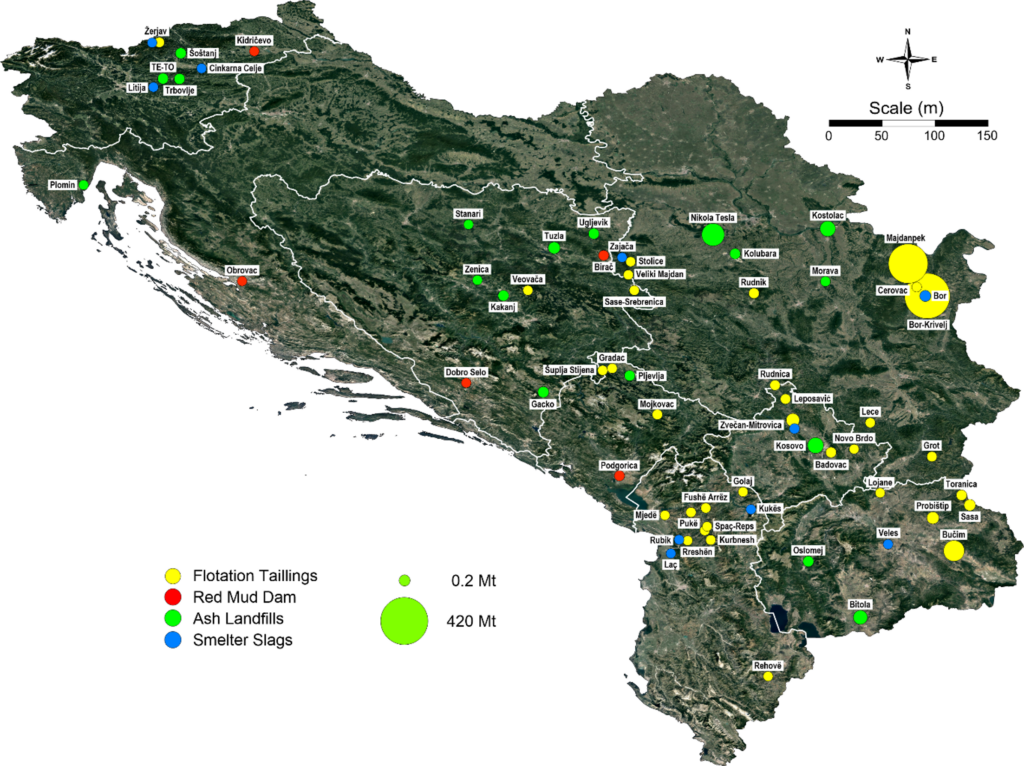

The result of this extensive research work is an in-depth overview of the areal distribution of secondary raw materials deposits from mining wastes in SEE.

The size of the circle in the map represents the size of the deposit; the topographic base is taken from Google Earth.

Diving into the results, it is clear that most landfills are for inert materials such as waste rocks, with 1653 landfills at 120 sites, followed by processing waste with 77 landfills at 48 sites, coal ash with 67 landfills at 24 sites, and metallurgical waste with 39 landfills at 24 sites. The total amount of all 2RM is about 3.2 billion tonnes in an area of about 100 km2.

The largest amounts of waste material have been found in copper flotation tailings at three sites: Bor-Krivelj (420 Mt) and Majdanpek (350 Mt) in Serbia, and Bučim (131 Mt) in North Macedonia. This is followed by coal ash landfills in the vicinity of the thermal power plants: Nikola Tesla (151.8 Mt) and Kostolac (68 Mt) in Serbia and Kosovo (73.2 Mt).

The importance of reusing, recovering, and recycling 2RMs from the extraction and processing sectors lies in the fact that those huge volumes are already on the surface of the Earth, fine-grained and almost ready for further innovative extraction methods.

FutuRaM will contribute to this goal by providing classification tools for 2RMs, as well as providing new data about the composition and quantities of a Copper flotation tailing in Bor (Serbia) demonstrating the UNFC classification of metal recovery.

Curious to know more? Have a look at these excellent publications:

Mining and metallurgical wastes: a review of recycling and re-use practices

Recovery of Rare Earth Elements from Mining Tailings: A Case Study for Generating Wealth from Waste