Brought to you by Gorazd Žibret, Špela Bavec from Geological survey of Slovenia and prof. Ivica Ristović and Nevena Stojković from University of Belgrade, Faculty of Mining and Geology

Mining and metallurgical waste, especially historical, could hold valuable resources. Under the right conditions, these historical tailings—at present considered waste—can be transformed into valuable resources. But to make this a reality, a solid system is needed for classifying, sampling and assessing these materials from economic, environmental, social and technical perspectives.

Why Do We Focus on Mining Waste?

As part of the FutuRaM Project, researchers are developing a new evaluation process based on the United Nations Framework Classification (UNFC) to assess the potential of material recovery from secondary sources, including mine waste. Mine waste is a broader term and includes various wastes generated during mining process (i.e. overburden, mine spoils), ore beneficiation (tailings and similar) and metallurgical process (slag, mud, chemicals and other waste). With declining mine production within the EU and reduced availability of domestic and imported concentrates, there is now a “shortage” of materials for smelting and refining processes.

As a result, old flotation tailings have gained attention as potential sources for the economically viable recovery of various metals and other useful components. This interest is further driven by the rising prices commodities, supply insecurities as well as the growing global demand for critical mineral raw materials. Reprocessing of old tailings could thus address resource shortages as well as mitigate environmental risks associated with their disposal.

Caste Study: Old Flotation Tailings

One of the FutuRaM case studies focuses on the Old Flotation Tailings (OFT) in Bor (Serbia) exploring how this waste could be repurposed and given new life. The exploration of the broader Bor metallogenetic zone has facilitated over a century of copper ore extraction, yielding significant quantities of copper metal, sulphur (processed into sulfuric acid), as well as gold and silver. However, this extensive mining activity has also led to the accumulation of approximately 207 million tons (Mt) of flotation tailings, 450 Mt of overburden, and 23 Mt of slag within the Bor municipality. The oldest flotation tailings (OFTs), which are used as FutuRaM case study, were generated during the first stages of copper mining and production in Bor. During that time, the high-grade parts of the ore body were extracted and processed, and it is expected that these flotation tailings contains metals in grades high enough to enable their economical extraction.

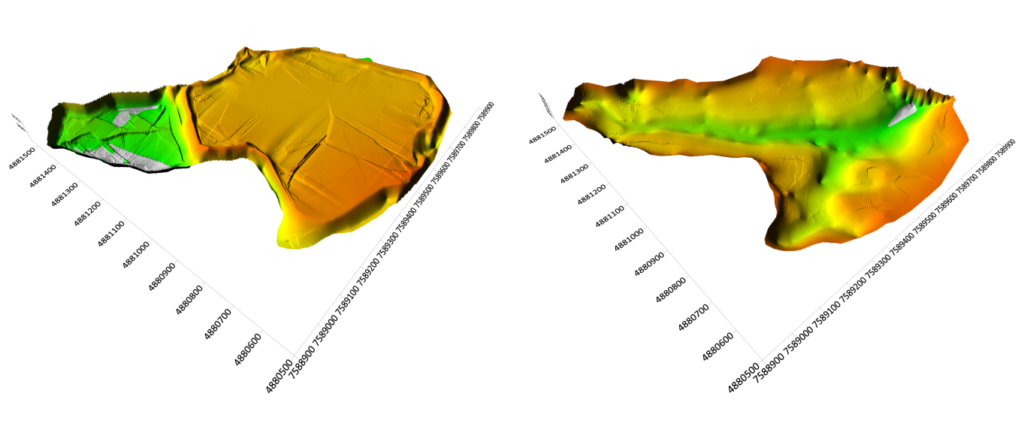

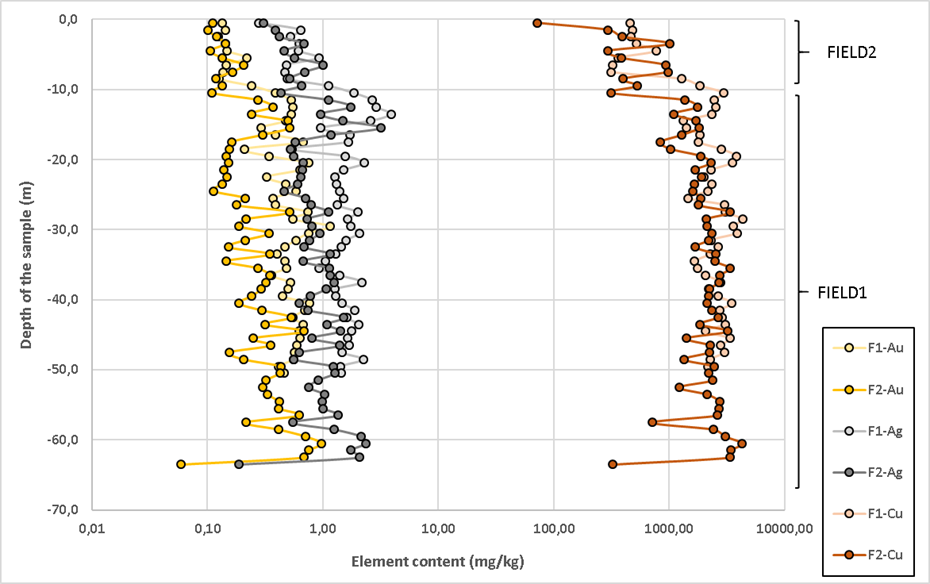

In the FutuRaM project, an exhaustive review of existing data on flotation tailings (OFTs) was conducted, supplemented by new fundamental geological research. This collaborative effort involved Geological survey of Slovenia, Faculty of mining and Geology (University of Belgrade) and Mining and Metallurgical Institute in Bor. In 2023, exploratory drilling was carried out, and core samples—both newly collected and from previous investigations—were analysed for strategic raw materials (SRMs) and critical raw materials (CRMs). To better understand potentials of tailings, additional investigations were made, including mineralogical analyses, observation of particles under scanning electron microscope and 3D modelling of the deposit.

The resulted 3D model of the deposit revealed that the tailings are composed of two fields:

- FIELD 2, which is the uppermost 10 m of relatively low-grade material, not identified as useful for the metal recovery,

- FIELD 1, composed of lower 60 m of the material, which is potentially interesting for metal recovery.

Identified and potentially interesting commodities are Cu, Au, Ag. It was established, that FIELD 2 contains 4.4 Mt of material, and needs to be removed prior extraction, while FIELD 1 contains 23.8 Mt of materials, with the median grade of 1.4 mg/kg of Ag, 0.23% of Cu and 0.36 mg/kg Au.

Considering geological level of knowledge, technical feasibility and environmental-socio-economic viability classification of resources and reserves of Au, Ag and Cu in these tailings by using UNFC classification system was made. It was established that Old Bor flotation tailings contains 102.173 t of Cu, 5.568 t of Au and 33.32 t of Ag, all within UNFC category 341 and UNFC class as “remaining product not developed”.